OXYGEN BARRIER FOR FLEXIBLE PACKAGING

In response to the growing emphasis on reducing plastic usage and minimizing food waste, the packaging industry has witnessed a rise in the adoption of barrier and ultra-high barrier packaging solutions to inhibit oxygen permeation.

These innovative packaging materials play a vital role in extending the shelf life of food products while indirectly contributing to the reduction of overall packaging production.

At NUREL, our dedicated research and development team focuses on two distinct lines of advancement: Promyde® copolyamides with modified gas permeability and Enoxite®, a high-performance alternative to EVOH for ultra-high barrier packaging applications.

Copolyamides for Oxigen Barrier Packaging

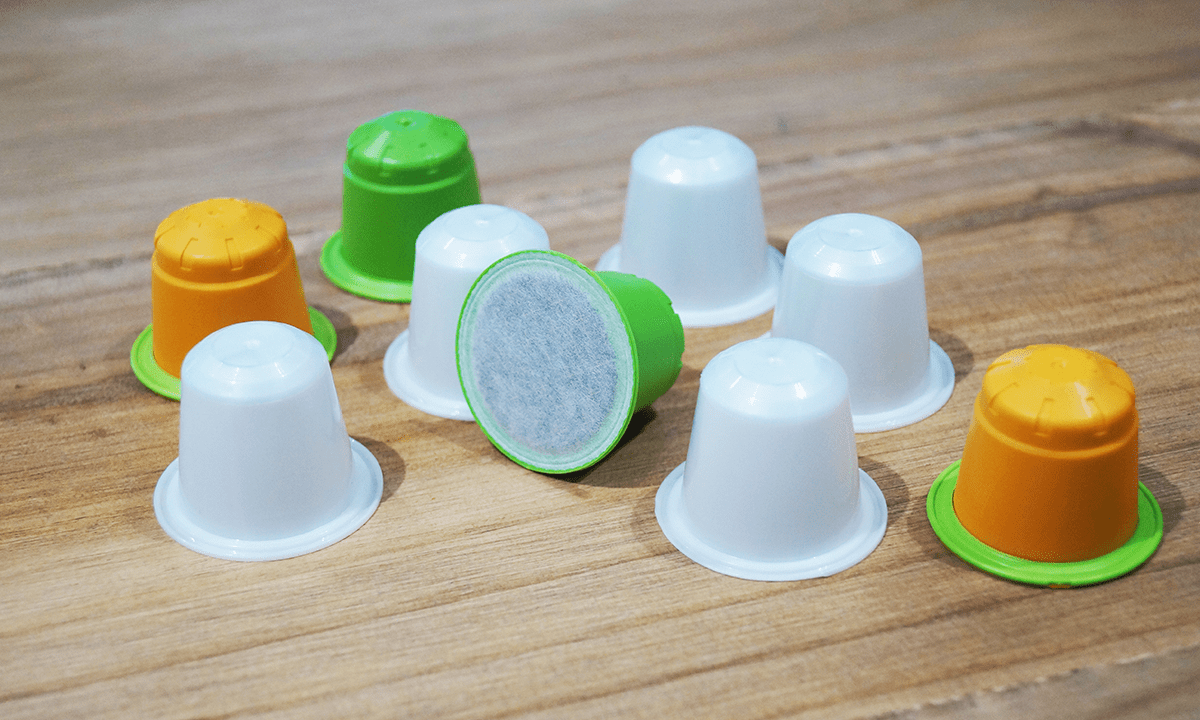

Polyamides are widely employed in food packaging due to their exceptional mechanical properties, tear resistance, puncture resistance, and barrier capabilities. Within our product portfolio, Promyde® BF740 and Promyde® BF745 provide effective solutions for packaging applications that necessitate oxygen barrier properties to enhance the longevity of food products. In multilayer structures, these copolyamides offer a suitable solution for retort applications, enabling a 50-60% reduction in the polyamide layer while maintaining optimal barrier performance. These containers, utilizing our copolyamides, not only have a lower carbon footprint but also align with the new European Union packaging design recommendations by being lighter and generating less waste.

Distinguished from traditional polyamides, our copolyamides exhibit remarkable oxygen barrier performance even under high ambient humidity conditions, making them highly desirable for containers subjected to thermal treatments like pasteurization and sterilization. Additionally, these copolyamides maintain transparency and exceptional thermoformability. With a process temperature of 200°C, they facilitate coextrusion with other polymers in both blown and cast extrusion processes.

CO2 PERMEABLE COPOLYAMIDES

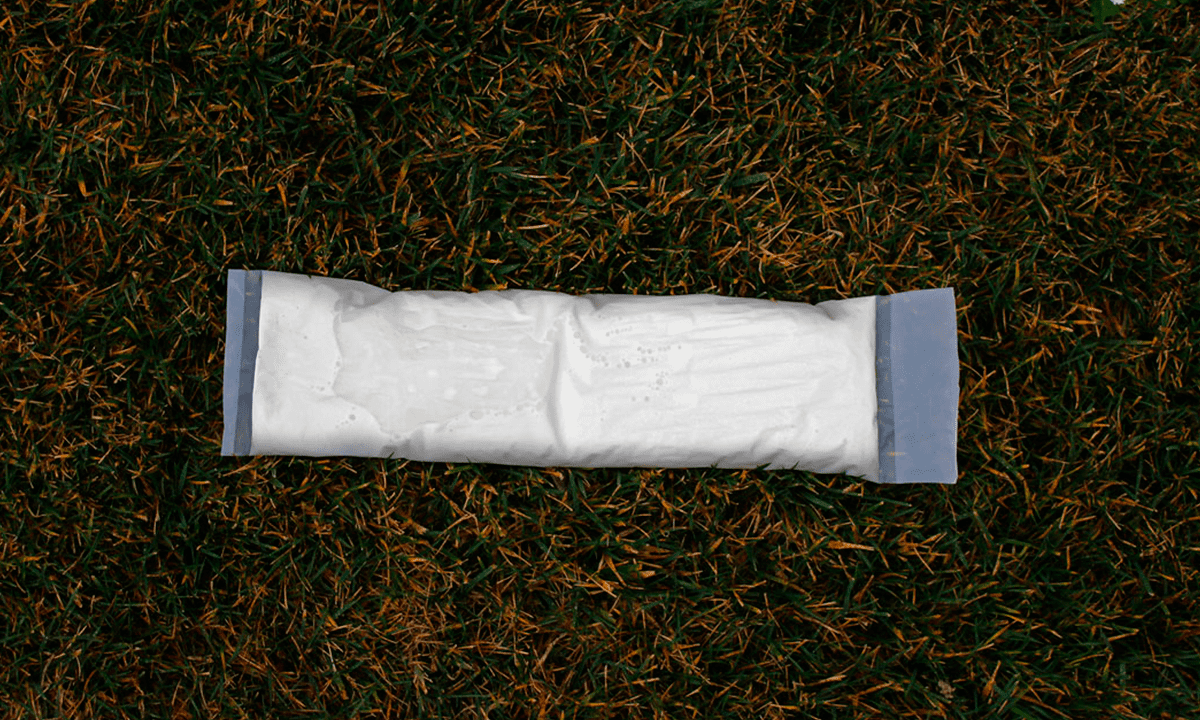

In addition, Promyde® BF640 copolyamide offers high transparency, superior puncture resistance, and tear strength four times greater than standard polyamide materials. Certain food products, such as cheese and poultry, naturally release CO2 or other gases during their shelf life. This gas release can cause container swelling and compromise packaging effectiveness over time. To address this issue, Promyde BF640 has been specifically designed to meet the requirements of applications necessitating CO2 permeability. Consequently, it serves as the ideal material for premium cheese packaging that must preserve the natural ripening process of the product. By utilizing films made with our BF640 copolyamides, which possess modified CO2 permeability, the gases released during the cheese ripening process can be adequately released.

CO2 PERMEABLE COPOLYAMIDES

In addition, Promyde® BF640 copolyamide offers high transparency, superior puncture resistance, and tear strength four times greater than standard polyamide materials. Certain food products, such as cheese and poultry, naturally release CO2 or other gases during their shelf life. This gas release can cause container swelling and compromise packaging effectiveness over time. To address this issue, Promyde BF640 has been specifically designed to meet the requirements of applications necessitating CO2 permeability. Consequently, it serves as the ideal material for premium cheese packaging that must preserve the natural ripening process of the product. By utilizing films made with our BF640 copolyamides, which possess modified CO2 permeability, the gases released during the cheese ripening process can be adequately released.

high oxygen barrier, alternative to EVOH

Enoxite® is a polymer that stands out for its ultra-high OXYGEN barrier properties.

The high demand for barrier packaging has led to a scarcity of barrier materials in the market. To address this issue, NUREL has introduced Enoxite®, an ultra-high barrier polymer for multilayer packaging, which is an alternative to the commonly used EVOH.

Apart from its excellent oxygen transmission rate (OTR) values, Enoxite possesses a revolutionary advantage: it is water-soluble, grease-resistant, and suitable for pasteurization applications. Enoxite product range encompasses various grades with different water solubility properties ranging from 20ºC to 50ºC, as well as different levels of flexibility.

Enoxite exhibits exceptional mechanical properties, rendering it an ideal choice for both flexible and rigid multilayer food packaging structures when combined with materials such as PE, PP, PET, PS, or PA. By opting for Enoxite as a substitute for EVOH, not only do you benefit from its superior performance, but it also contributes to the sustainability of multilayer film structures by enhancing recyclability through its solubility. For further details regarding the Enoxite product range, please click here.

Applications

Cheese packaging

Cheese packaging is essential to guarantee the quality, safety, and freshness of the product. It must meet a series of requirements to protect the cheese from oxidation, dehydration, and preserve its maturation process. NUREL offers solutions that adapt to these requirements by providing packaging with barrier properties and oxygen permeability.

Meat and bone-in meat packaging

Packaging for sharp-edged foods requires high puncture resistance, flexibility, moisture barrier, transparency, and an attractive gloss. NUREL offers a range of special copolyamides and polymers with high oxygen barrier properties for the manufacturing of vacuum bags and thermoformed packaging for meat.

Skin Packaging

Skin packaging is gaining popularity due to its lightweight and visually appealing design, as well as its superior technical performance. NUREL provides specially formulated copolyamides that exhibit exceptional strength, sealing capabilities, barrier properties, and unmatched glossiness.

Stand-up pouches

NUREL offers a complete range of Polyamide 6, Copolyamides and Ultra-High barrier materials for Doypacks. PA-based film materials not only help extend the shelf life of packaged food but also contribute to reducing plastic usage. Promyde polyamides offer excellent mechanical and barrier properties while providing an appealing packaging finish, thanks to their glossy appearance.

Deep thermoforming

Deep thermoformed packaging is extensively utilized nowadays due to its numerous benefits, including lightweight, transparency, and gas barrier properties, necessitating the use of materials with high technical performance for its production.

Related markets

Packaging

Polyamides are used in the packaging industry for their good mechanical properties, barrier properties and for providing a quality finish due to their high gloss and transparency.

Do you want to know all the news of Nurel Polymers?

Subscribe to the Newsletter