COMPANY

MORE THAN 50 YEARS OF NYLON 6 & 66 PRODUCTION

NUREL FIBERS

NUREL started its operations producing polyamide fiber in 1968 and i was acquired by SAMCA Group. The entrance of SAMCA Group in 1999 brought successive investments in new polymerization and spinning technologies. Now NUREL is the reliable and high quality supplier of reference of nylon 6 and 66 for the textile market.

AT THE FOREFRONT OF EUROPEAN TEXTILE INNOVATION

At NUREL, we have two nylon spinning plants and state-of-the-art draw-warping facilities, enabling us to offer a unique range of products for lingerie, swimwear, sports, and technical applications. Our products meet the expectations of the most demanding customers in the market.

Our ongoing investment in Technology and R&D+i demonstrates our strong commitment to the future of the textile industry. Our innovation efforts are focused on incorporating new technologies such as nanotechnology, smart textiles, and other advanced textile functionalization programs.

PRODUCED LOCALLY WITH A GLOBAL ENVISION

Our plant in Zaragoza, Spain, is structured into three distinct business units: ENGINEERING POLYMERS, BIOPOLYMERS, and SYNTHETIC FIBRES. Together, these units generate a combined turnover of 170 million euros, with a polymerization capacity of 27,000 tons, 49.000 tons of compounds and a yarn production of 7,500 tons. Currently, NUREL employs 350 people. Approximately 75% of our nylon fiber production is exported to major European and Asian markets.

La multinacional petroquímica americana ESSO desarrolla el proyecto de ingeniería para la construcción de una planta de producción de nylon en el barrio de Santa Isabel, Zaragoza.

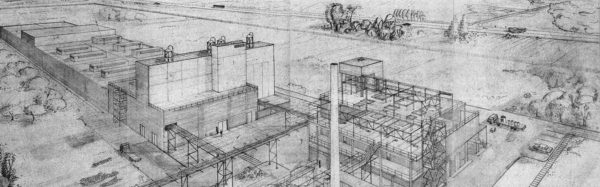

Se lleva a cabo la construcción y acondicionamiento de la planta de polimerización (P1) con cuatro líneas, la planta de hilatura (H1) con diversas secciones, las oficinas e instalaciones de servicios.

El 10 de diciembre se comienza la producción en planta con 550 empleados. En el año siguiente se realiza la inauguración oficial, acudiendo al evento los ministros de Industria y de Plan de Desarrollo.

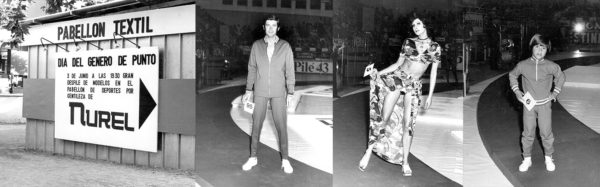

Se comienzan a publicitar los tejidos producidos nylon de Fibras ESSO mediante pases de modelos a lo largo de la geografía española y acudiendo a ferias. La marca comercial de las fibras de nylon es NUREL.

La planta pasa a manos del Banco Industrial del Mediterráneo y, posteriormente, a la compañía inglesa Imperial Chemical Industries. Es renombrada a partir de la marca, NUREL, y comienza el desarrollo de una nueva planta de producción de poliéster.

El 25 de enero de se inaugura la planta de hilo de poliéster junto al Ministro de Industria. Se inicia la producción diaria de 75 toneladas, bajo la marca comercial de fibras de poliéster: TERYLENE.

A final de década se pone en marcha una planta de recuperación de caprolactama y de despolimerización de desperdicio industrial para su reciclado. NUREL alcanza su máximo histórico de empleados, 1503.

NUREL cuenta con una red logística propia, almacenes de distribución y una oficina central en Barcelona donde se encontraban algunos de los departamentos más importantes.

Se inaugura una planta de cogeneración que convierte, hasta 2005, energía primaria en energía eléctrica y calor. Se comienza a trabajar con PCs y un sistema de gestión IBM-AS-400 con varios terminales.

NUREL obtiene la certificación ISO 9001,de gestión y aseguramiento de la calidad. Un año más tarde, el equipo directivo adquiere la planta ante la intención de cierre por parte de ICI.

Se efectúa un cambio de producción de LOY a POY, se instala la primera unidad de estiro-urdido y comienzan nuevos desarrollos en polimerización. Se lanza la marca de hilos multifilamento: NOVAREL.

El grupo empresarial aragonés SAMCA realiza la compra de la planta de producción de NUREL a la propiedad anterior. En verano de 1999 se lanza la primera web de la historia de NUREL.

NUREL consigue la certificación ISO 14001 de Gestión Medioambiental, que certifica la identificación de los riesgos medioambientales y la aplicación de procedimientos de prevención para evitar accidentes medioambientales.

Se pone en marcha una nueva planta de polimerización de poliamida (P2), una nueva planta de hilatura (H2) y una unidad de reciclado mecánico. Comienzan a producirse las microfibras.

Se crea la división plástica de NUREL ya que, hasta el momento, todo el polímero producido en planta era utilizado para autoabastecerse. Al año siguiente se lanza la marca comercial: NOVAMID.

Se publica la primera patente relativa a la tecnología de encapsulación que usa NUREL, siendo la única empresa del sector en producir fibras cosméticas. NUREL lanza la gama de cosmetotextiles con NOVAREL Aloe.

Se realizan unas modificaciones en planta para poder producir nuevas recetas de alta viscosidad aptas para film, permitiendo a NUREL entrar en este mercado. Se inicia la producción de hilo de nylon 66 en hilatura.

En enero se inaugura una moderna planta de hilatura de nylon H3 que sustituye a la original de 1968 (H1). Un año más tarde se relanza la división plástica con una nueva marca: PROMYDE.

Se instala una unidad de Solid State Postcondensation, para producir poliamida de alta viscosidad a gran escala, consolidando a NUREL en el mercado del packaging y productos semielaborados.

Optando por un desarrollo industrial más sostenible, se amplia el negocio con la puesta en marcha de una nueva planta de de biopolímeros, INZEA. NUREL obtiene la certificación ISO 50001 y se crea la sub-empresa cosmética ZEOMETIC.

Se instala una nueva unidad de extrusión para fabricar compounds de poliamida y se renueva la línea de replastificado, que permite recuperar el desperdicio industrial y reconvertirlo en granza apta para producción.

NUREL cumple 50 años con 350 empleados y produce 16.000 toneladas anuales de compounds, 27.000 toneladas anuales de polímero de poliamida, 2.000 toneladas anuales de polímero reciclado y 7.200 toneladas anuales de hilo continuo de nylon.

NUREL desarrolla y presenta una nueva gama de productos de compounds basados en PBT y PET, bajo la marca Terylene, ampliando nuestros mercados en los sectores del automóvil y eléctrico.

Siguiendo el compromiso de la compañía con el medio ambiente, se instalan 22.568 paneles solares en el suelo y las cubiertas del área industrial de NUREL, convirtiéndose en una de las instalaciones de autoconsumo sin vertido a la red más grandes de Europa. Dada la creciente demanda de plásticos más sostenibles, se pone en marcha una segunda línea de extrusión de biopolímeros INZEA.