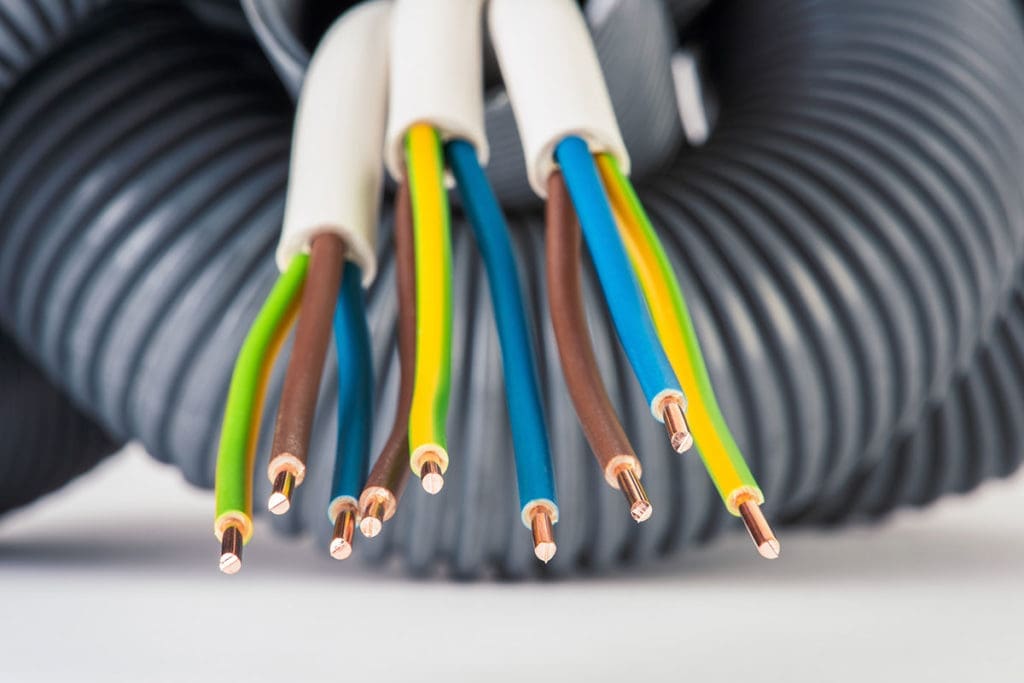

PA6 for cable jacketing

Promyde PA possesses unique properties that make it an outstanding choice for enhancing the performance and protection of cables in various industries. It is frequently employed as a sheathing material for THHN, THWN, and TFFN cable types, providing a perfect protection and insulation.

The high-viscosity range of Promyde PA 6 stands out due to its outstanding attributes, including exceptional impact resistance, strength, high tenacity even in extreme temperatures, low abrasion, excellent process performance, effective electrical insulation, and chemical resistance. .

Main advantages of promyde PA for THHN, THWN and TFFN cables

- Internal and external wiring: Promyde is adaptable for both internal and external wiring, catering to indoor and outdoor use with diverse performance requirements, even in high-pressure and extreme temperature environments, as well as stationary and moving mechanical settings.

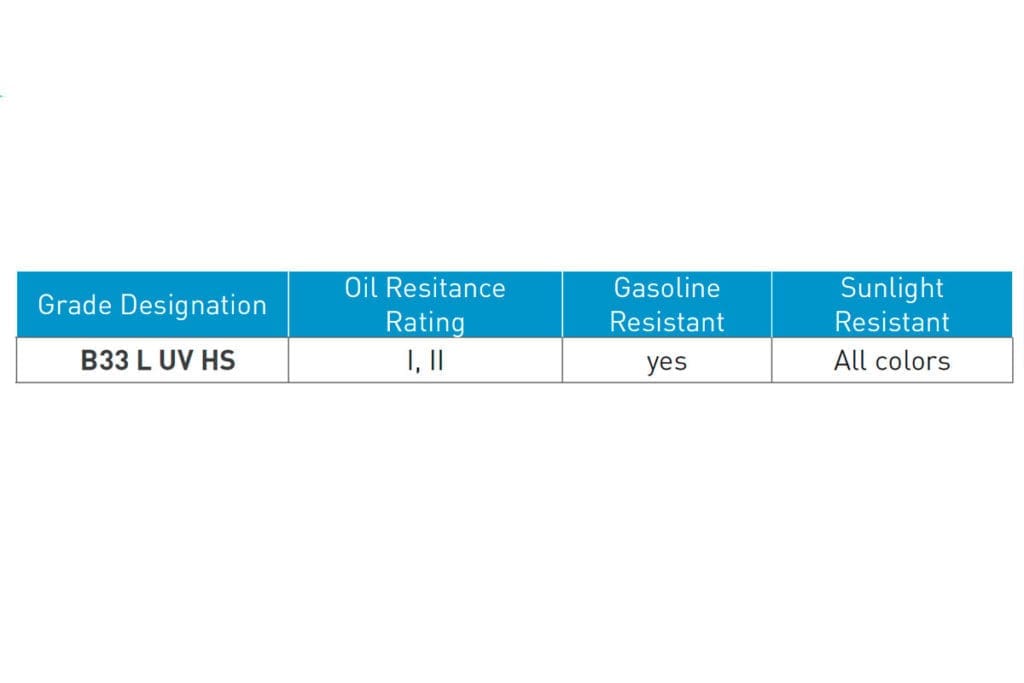

- UV PROTECTION: Cables with external polyamide jacketing exposed to natural light benefit from increased durability with Promyde B33 L UV HS, UL83 Certified.

- Precise Diameter: During the extrusion process, Promyde PA6 ensures consistent wire thickness, even in critical processes like micro and millimeter extrusions.

- High Thermal Resistance: PA exhibits excellent thermal resistance, preventing thermal deformation and allowing cables to function effectively across a wide temperature range.

- Heat resistance properties: With a melting temperature of 220°C and excellent long-term high-temperature performance, PA 6 is an optimal choice for low-voltage cable sheathing.

- Flame Retardance: Promyde PA exhibits flame retardant properties, enhancing cable safety in fire or high-temperature scenarios.

- Reduced Coat Thickness: Thanks to its exceptional mechanical properties, Promyde PA6 grades for cable jacketing can be extruded with reduced thickness while maintaining insulation performance. This enables more wires in a conduit or a higher copper content in a single wire.

- Flexible properties: Promyde PA6’s flexibility allows cables to bend and adapt to various installation scenarios without compromising their structural integrity, making it ideal for tight spaces and complex cable routing.

- Chemical Resistance: PA’s resistance to chemicals and oils ensures that cable jackets remain protected and functional, even in chemically challenging environments.

- Self-lubrication properties: Promyde PA6’s self-lubricating properties facilitate the installation of wires, simplifying the cable installation process.

Resistance in extreme conditions

- Tensile strength at extreme temperatures.

- Thermal stability for optimal performance in motion and under temperature fluctuations.

- Suitable for indoor and outdoor use.

- Extended durability under UV light ( UL83 Certified).

Applications of PA Cable Jacketing

-

Telecommunications: PA jacketed cables are commonly used in the telecommunications industry, providing robust protection for data transmission cables, fiber optics, and more.

-

Automotive: In vehicles, PA cable jacketing plays a vital role in ensuring the reliable operation of various electrical systems

-

Industrial Settings and construction: Industrial cables benefit from PA jacketing due to its resistance to harsh chemicals, extreme temperatures and mechanical stress,.

Products

Download our catalogues

Promyde - Extrusion

Want to stay updated on the latest on NUREL Technical Polymers?

Subscribe to the Newsletter